INNOVATION OF THE VIPER

Manufacturing of aircraft requires extensive theoretical and practical experience in the field of engineering, cutting, machining, forming and processing of metals, laminates and other materials, mechanics, aerodynamics, electrical and other industries. Production of Viper SD4 is realized by the precise work of specialists, who have extensive experience in these fields.

The following is a brief demonstration of work activities during production process of the Viper.

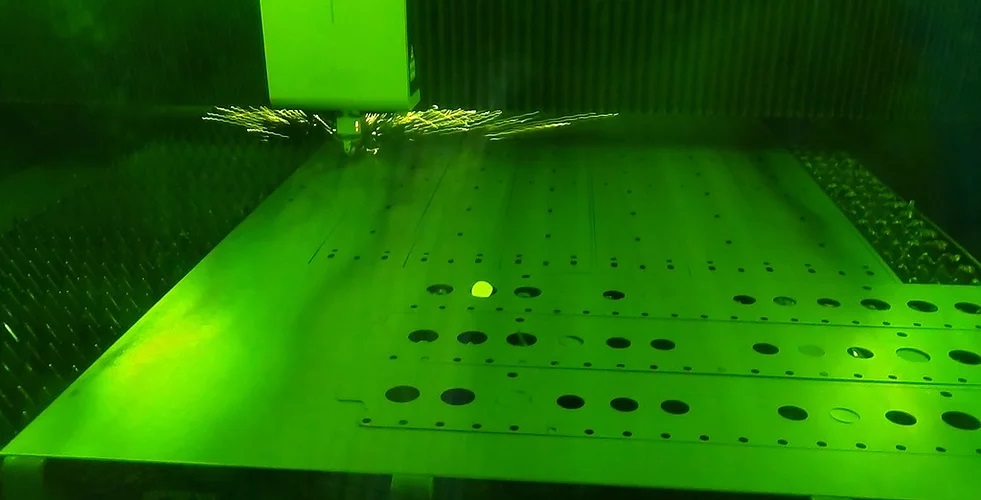

STEP ONE

Initial production is based on laser cutting of sheet metal which can cut parts of the highest quality. Thereafter the sheet metal is bent and the shape is changed to suit the aircraft.

STEP TWO

A riveting process is used to join the various parts of the aircraft together.

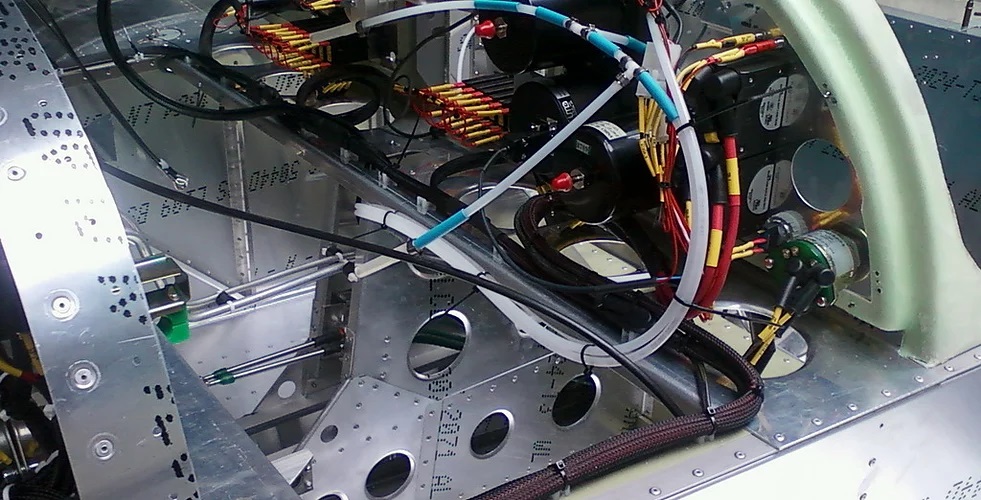

STEP THREE

Extreme care is taken with the installation of wiring harnesses and instrumentation.

STEP FOUR

The entire production process is subjected to intense procedures for quality, control and functionality.

STEP FIVE

Final inspection verifies all components before the aircraft is deemed ready for delivery.

THE RESULT

The entire process, from initial production to final inspection is carried out with an emphasis on accuracy, precision, and observance of the highest quality for all operations.

Don't Settle For Less

Contact Details

Inquiries

For any inquiries, please call: +61 (0) 428 919 409 or fill out the following form

Our Location

Brisbane/Gold Coast Australia

Andre Vuilleumier: 0428 919 409

Michel Vuilleumier: 0422 759 413

E-pos: info@viperaircraftaustralia.com